Green Laundry & Garment Dyeing Machines

Integration of Washing, Garment Dyeing, and Water Recycling

Our Green Laundry & Dyeing machine integrates washing, garment dyeing, and wastewater recycling. It is mainly designed to suit B-group end-users such as garment manufacturing units, textile industries, hotels, lodges, hostels, hospitals, and apartments. As most B-group users face difficulty in technical management, cost and complexity of the process, they outsource almost 80% of their work. However, with the digital technical management system, multi-functional capability and user-friendly operation, our new wet-processing machine can be a promising solution them. Moreover, the garment-dyeing and soft-feel creation features add value in terms of income-generating capability. This machine can also be tailored for the A-group end-users.

Main Features of the Technology

Efficient and Multi-Functional Laundry Process

Most existing laundry processes require specific chemicals dosage, quantity of water, and technical washing to remove the dirt, stains and dust. For this purpose, our machine has automated user-interface for selecting the required function of stain/dust/dirt removal without technical burden. Moreover, the machine can control chemical dosage, PH, washing rotation, drum rotation, water quantity, operating temperature, and discharge time.

Stain Removal

The stain removal mechanism guarantees the following types of stains:

-

- Acid Stain

- Alcohol Stains

- Ball Point Ink Stain

- Blood Stain

- (Candle) Wax Stain

- Carbon Paper & Black Soot Stain

- Chewing Gum Stain

- Chocolate stain

- Coffee & Tea stain

- Crayons Stain

- Dyes & Colors Runs

- Egg Stains

- Glues, Gums & Cellulose Adhesives Stain

- Grass Stains

- Milk & Ice Cream Stain

- Lipstick & Makeup Stain

- Mud Stain

- Nail Polish Stain

- Oils, Light sewing machine, cooking oil, baby oil Stain.

- Ointment Stain

- Paint Stain

- Permanent Markers Stain

Wastewater Treatment & Recycling

A very promising option in our machine is we can recycle almost 98% of the used water back to the machine, which make the process fully sustainable.

Comparison of Existing Technology with our Technology

| Existing Technology | Our Technology |

|---|---|

| Only 20% is done, and the remaining 80% is outsourced | Complete process is done |

| Needs skilled technician for operation and maintenance | Fully automated with technical management Easily operatable by non-technical person. |

| High energy cost | 50% saving in energy cost |

| Separate washing and drying | Integrated washing and drying |

| Requires large space | Saves 50% space and can be operated on the terrace |

| Less portability | Fully portable |

| Approximate process timing | Accurate process timing |

| Approximate chemical dosage | Accurate chemical dosage |

| Manual follow-up of process steps | Process steps are automated |

| Process is complicated to the end users | Process is user-friendly |

| Chances of wastage of chemicals, time, water, cost, and process | Zero wastage |

Garment Dyeing & Soft feel Creation

Garment Dyeing

Our garment dyeing process offers color guarantee. At present, B group end-users cannot do this process because the color combination, dyes ratio and other chemical dosing, need a skilled technician. For example, the reactive dyeing method requires knowledge and technical monitoring of chemicals such as auxiliaries of leveling agent, dyes ratio, PH for the required process, temperature for different stages, enzymes ratio for yarn fiber Infiltration process, hot and cold-water process timing for color fixing process, softener ratio for soft feel creation, time required for penetration of chemicals into clothing, and water ratio for garment quantity, which demands technical monitoring. Our novel technology offers easy handling of all these processes for B group of end-users by non-technical operators.

Soft feel Creation

For soft-feel creation on clothes, the cotton garment manufacturing industries currently use stone wash, silicon wash, bio polish wash, semi enzyme wash garment processing, garment finishing, special washes, cotton garment wash, polyester garment wash, rinse wash, dirty wash, stone wash, normal garment wash, enzyme wash, softener wash, bio polish wash, stone enzyme wash, stiffener wash, crush wash, semi enzyme wash, tie and dye , reflected wash, silicon softener finish, seam effect wash, magic wash, patch effect wash, amber combi fitch wash, raw wash, ice bleach wash, vintage wash, glitter wash, silicon softener wash, semi enzyme wash, heavy enzyme wash, distress wash, acid wash, ppt wash, leather finish, paper touch finish, seersucker wash, crinkle wash, tone adjustment wash, stone enzyme with grinding, heavy distress wash, heavy sand silk wash, and so on.

Due to the complexities involved, the B group end-users usually outsource the soft feel creation, which incurs additional cost but cannot guarantee the required quality. However, our technology provides an intellectual solution that saves time, energy, and cost, by optimizing the chemical dosage, PH management, temperature control, water input ratio, water discharge time according to the required soft feel requirement. After some initial manual treatment, the entire process can be done by our new technology without the need of a skilled technician.

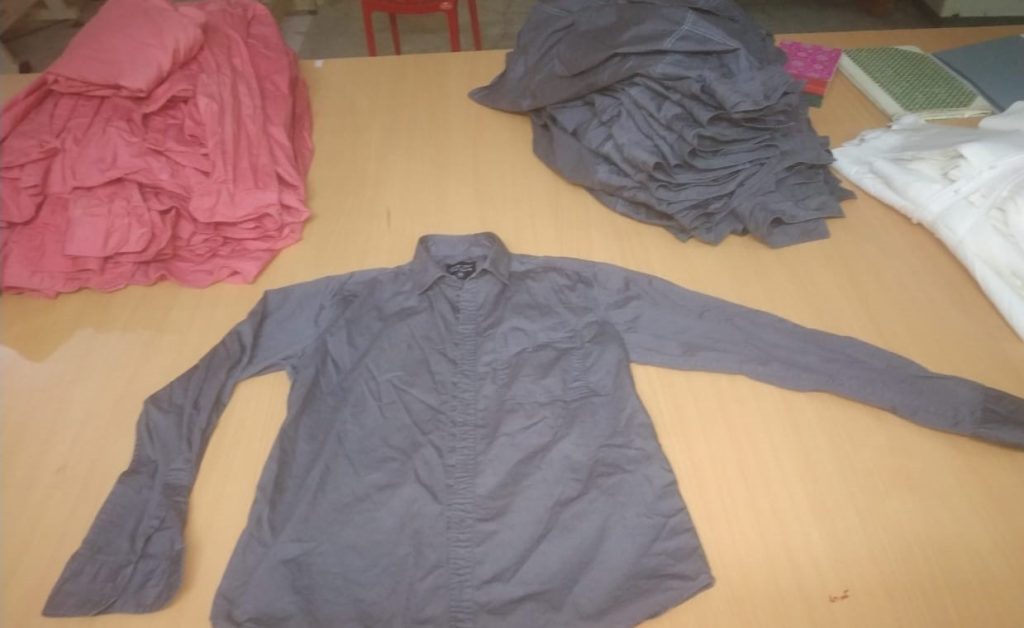

Our Branded Cotton Shirts

Our Ninety NineTM brand pure cotton shirts are gaining encouraging customer feedback in terms of quality, softness, comfort, and cost. Our new brand would be the most affordable alternative of the costly top brands in the market.